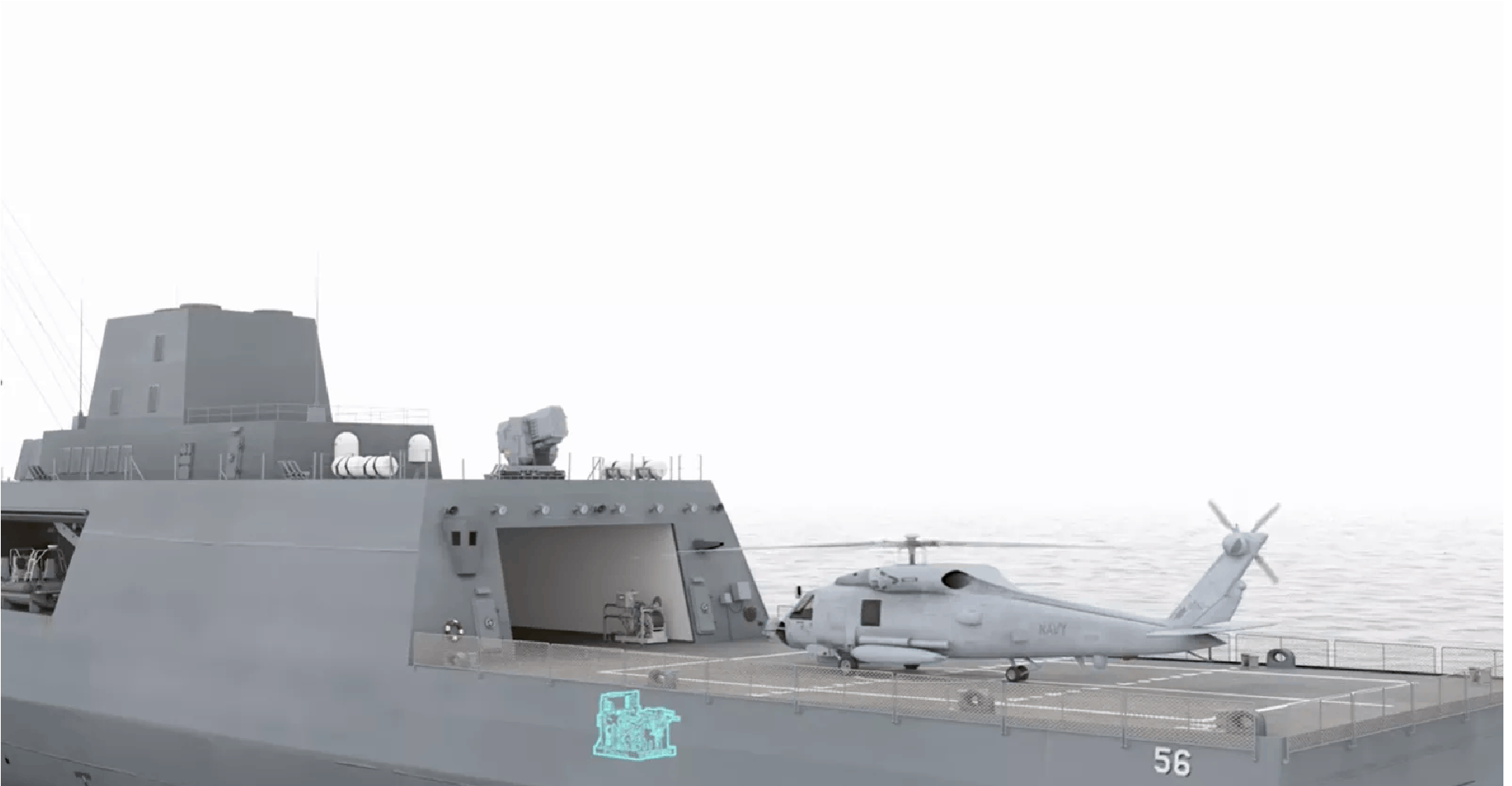

Easier and affordable on-board helicopter refueling at naval standards

DESMI introduces a new ship-based helicopter fueling system that not only makes it less expensive but also much easier to service and maintain.

Navies and coast guards of the world now have the possibility to get a ship-based helicopter fueling system with several advantages that not only make it better, but cheaper, too.

These advantages include a new, modular design for lower overall cost and faster maintenance, lighter weight, an improved user interface that makes it easier to operate, and an integrated logistics system. All of this is in a proven design at NATO STANAG standards. This includes options for both on-deck or Helicopter In-Flight Refueling (HIFR).

“This will be a wonderful benefit to the navies and coast guards of the world, both technically and commercially. Taxpayers will truly get value for their dollar,” says Christian Wollerup, Segment Director for Defence and Fuel Products at DESMI.

Modular design

As a market leader in helicopter refueling systems, DESMI has previously customized each unit for every customer, depending on their needs. While that option is still available, it comes at a cost. So DESMI has introduced a system built in modules – where customers can choose among the different pieces that fit together – “a bit like Lego bricks” – into a whole unit, according to Christian.

The modules’ combinable pieces include pump units, filter units, control systems and dispenser units. Each module has up to several different options – with 21 modules in all.

For example, the customer chooses the type and number of pumps in the pump unit, the number of filters needed, the type of control system, and so on. The modularlisation means DESMI can use standardised products in each module, bringing the cost down.

Thus, customers in India, Singapore, USA, Canada, the UK, Germany, France, Italy or Spain can build a complete, modular system with the standard components for their own navy’s or coast guard’s specific needs.

In addition, the new design allows easy access to all components in the finished design for easy maintenance. “There’s basically not one component that you can’t replace within 15 to 30 minutes,” Christian says. “In other systems, it can take considerably longer. So basically, we’re reducing downtime during maintenance considerably.”

Lighter and safer

DESMI offers the new system in three different sizes: 230 litres per minute (l/m), 480 l/m and 680 l/m.

Each system comes with an optimized bottom plate in order to save weight and increase strength. Thus, ship designers will save 20% on weight of the helicopter fuel system with the new DESMI products – a benefit for warships that need to cut down on weight whenever possible.

In addition to the lighter base plate, DESMI has introduced vane pumps to the design. Fuel enters through a prefilter to the pump, then it passes through a safety valve and then a filter water separator. This filter, along with a brand new water barrier technology on the dispenser unit, serves the important purpose to make the fuel clean and dry. It separates water droplets down to 5 ppm, and it also removes solid contaminants. As of this writing, the water barrier technology is still in final testing. Once it is approved, DESMI will retrofit the new water barrier technology into new modular systems by just changing a pipe and the filter, thereby helping customers to achieve even safer operations in austere conditions.

As with previous DESMI refueling systems, the new system is also optimised for HIFR operations – for refueling during extreme waves or weather, when it is too difficult for the helicopter to land safely on board. Also as previously, the system has been “designed from the tank all the way up to the helicopter,” ensuring safe and dry fuel in any operation scenario.

Integrated logistics system

Naval and coast guard ships must have maximum operation time in their area, any day, every year, as long as they operate. DESMI has designed its logistics system with that in mind. The Integrated Logistics System (ILS) is a digital database with a maintenance manual, pictures, spare parts numbers, troubleshooting schematics and more in one package. It is made for the naval helicopter refueling operators and maintainers. In addition, technical and animated videos show in detail how the system works. The ILS is both in digital format and hard copy, in an easy to use format to minimise downtime and maximise operational capability.

Improved user interface

The user interface makes the DESMI refueling system easy to operate for both the helicopter landing officer and helicopter landing assistants on the flight deck during HIFR.

“For the maintenance personnel, it makes me extremely happy that we have a system which is easy to operate and easy to maintain, should there be a fault. Easy troubleshooting,” says Christian Wollerup.

Naval standards

The system is built by marine engineers for marine engineers. It complies with naval classification standards such as LR, DNV-GL as well as other classification societies upon request. The system also complies with NATO STANAG standards – not commercial standards. While a commercial system provider can supply a helicopter refueling unit for an oil rig in Southeast Asia or the North Sea, for example, naval and coast guard surface ships have different standards. DESMI’s maritime refueling systems comply with such standards.

They are designed to cope with “outside events”. In other words, DESMI can shock-mount the system so that it can sustain hits from torpedoes, missiles or mines and still be able to operate both during, under and after such an event.

“That’s quite unique. And that is what makes the difference if the naval customer is requesting a unit to comply with naval standards,” says Christian.

The new system will be ready for the market in January 2021. When the COVID-19 travel ban is over, DESMI will be attending all major exhibitions to present the system.

Furthermore, DESMI offers classroom training or onboard training for its helicopter refueling systems. This is typcially done by DESMI’s superintendant engineers, who have many years of experience with these systems – offering training in both automation and mechanics of the system.