Evaluating CO2 production with NavCad for dual-fuel and duty profile analysis

Author: Donald MacPherson, Technical Director, HydroComp, Inc.

Design-For-Sustainability is not a new topic in the ship design community but effectively conducting CO2 prediction has become more significant as attention is focused on regulatory compliance. The upcoming EEXI and CII regulations (as well as the existing EEDI and EEOI) has generated considerable interest in dual-fuel engines for reduction of CO2 GHG emissions – both for new construction, but also for retrofit conversions. This article describes the methodology and analytical process of HydroComp NavCad® Premium Edition to provide meaningful and accessible prediction of CO2 production.

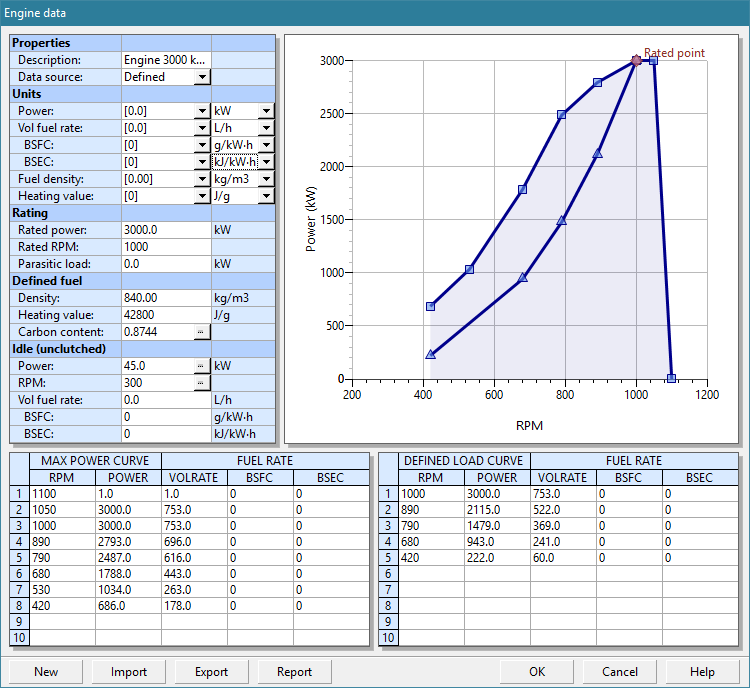

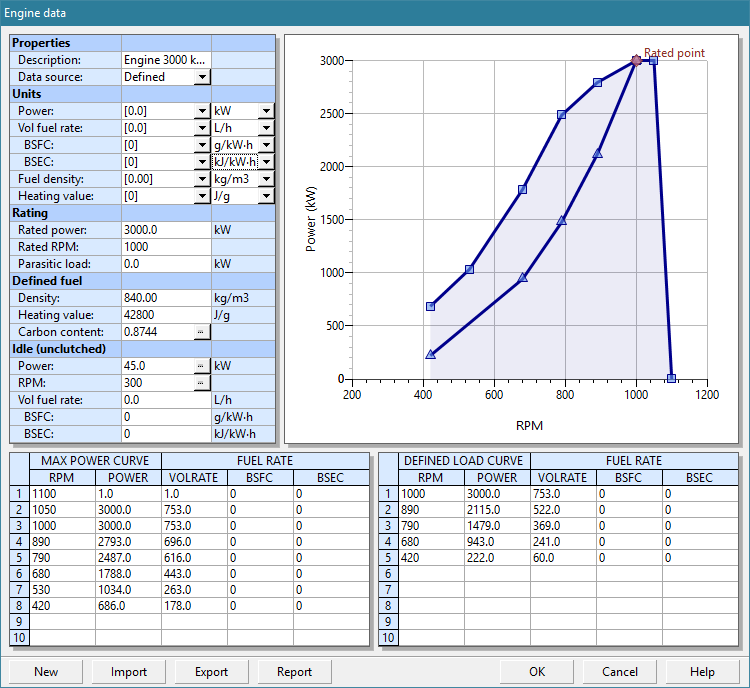

Definition of engine fuel consumption

Until recently, the prediction of fuel rate in NavCad utilized a traditional Volumetric fuel rate (e.g., L/h) for propulsion analyses. This was sufficient for “always-liquid fuels” but was not sufficient to properly model potentially “non-liquid” fuel types (such as LNG), nor to compare fuels in a dual-fuel setting. To account for this – and for how dual-fuel engine manufacturers typically publish consumption information for their engine models – the NavCad engine model definition for fuel consumption was updated with several new data items. These include Density, Heating value, Brake Specific Fuel Consumption (BSFC; e.g., g/kW-h), and Brake Specific Energy Consumption (BSEC; e.g., kJ/kW-h).

Engine definition form

The user-entered Defined fuel information also allows for a non-standard fuel specification be used in propulsion calculations. This provides a means to account for corrections to fuel quality and energy storage.

Equivalent energy fuel model

In consultation with dual-fuel engine manufacturers, NavCad was updated with a common “equivalent energy” fuel consumption model. The basis for the model is that engine power is a function of the fuel’s energy properties, and not solely its volumetric or mass properties. Therefore, all fuel consumption calculations in NavCad were updated to initially convert the defined engine fuel properties to an energy basis (BSEC), and then to correct volumetric and mass fuel rates using the Density and Heating value properties for the selected fuel(s).

Prediction of CO2 greenhouse gas production

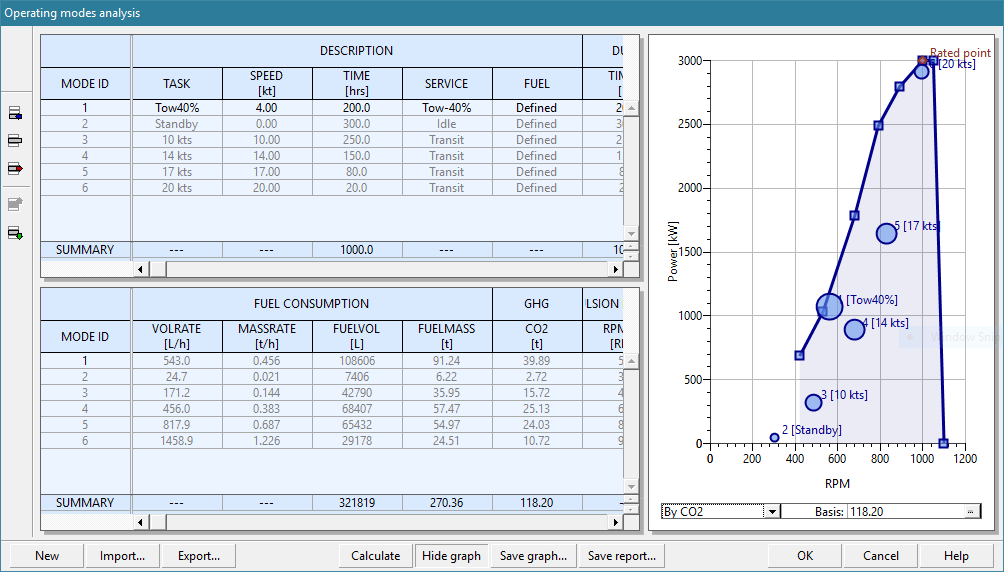

As mentioned, one of the most significant recent design drivers is greenhouse gas production, thus requiring the ability to predict the generation of CO2. Calculation of CO2 production was added to the steady-state Propulsion system analysis (per engine), and to the Operating modes analysis tool (as the total per mode). The methodology for prediction of CO2 is based on the “carbon content” ratio of the mass fuel consumption. In other words, a prescribed portion of a fuel’s mass is defined as its unburned carbon content.

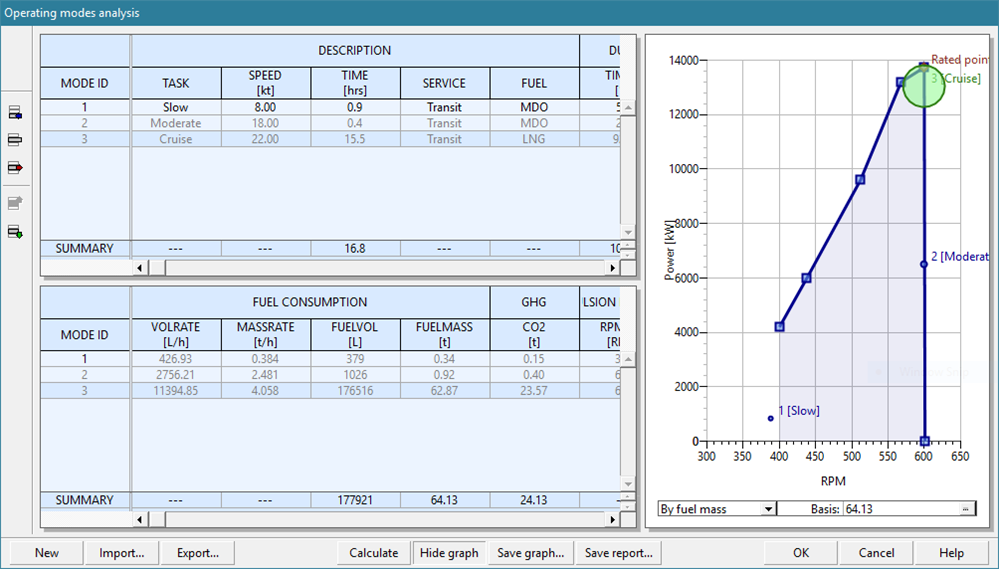

For use with the Operating modes analysis module in NavCad, the CO2 production is calculated for each mode then summed for the total for a duty profile (by the duration of each mode) or a voyage (by distance of transit legs). This module allows definition of individual mode parameters, including engine count (for Idle operation or Compound gearbox) and the fuel type specified for the mode, as well as calculation of the mode’s total fuel demand. A plot of CO2 production is also shown (an example of which is seen below), whereby the size of the marker reflects the relative production. The position of the marker (by power and RPM) indicates the relationship of CO2 production with the engine loading. This plot is a valuable means to communicate the impact of ship and propulsion design decisions to stakeholders.

Operating modes analysis calculation (for a generic example project) and display of CO2 production

Definition of fuel carbon content

The analytical prediction of CO2 greenhouse gas production required definition of the carbon content of both the defined fuel, as well as the Primary and Secondary fuel types selected in the propulsion system and operating modes analyses. Carbon content values for standard fuel types are available as optional selections. Values for the carbon content of the four standard fuels which are available for quick selection in NavCad (MGO, MDO, HFO, LNG) are taken from the IMO MEPC 281 (70) reference.

In summary

As various sustainability initiatives include the calculation of CO2 greenhouse gas production for a variety of different fuel types and dual-fuel operation, updates developed for NavCad include:

- Calculation and reporting of the fuel consumption of two user-selected fuels during propulsion analyses. These are indicated as Primary and Secondary fuels.

- Easy user-selection of standard fuel types (in addition to the Defined types entered for the engine definition). Four standard fuel options have been added to NavCad: Marine Gas Oil (MGO), Marine Diesel Oil (MDO), Heavy Fuel Oil (HFO), and Liquid Natural Gas (LNG). Values for density and heating value (i.e., lower calorific value) of these four standard fuels are taken from the IMO MEPC 281 (70) reference.

- In addition to the calculation of fuel consumption for the Primary and (optionally) the Secondary fuel selections, NavCad’s Operating modes analysis was updated to allow the user to identify the fuel selection (Primary or Secondary) for individual modes. Plots of fuel use are available for both total volumetric and mass fuel consumption for the voyage, with color coding for fuel type (blue=Primary, green=Secondary; as shown in the example below).

Operating modes analysis calculation (for subject vessel) and plot of fuel consumption

References

IMO MEPC 281 (70). RESOLUTION MEPC.281(70) (Adopted on 28 October 2016) Amendments To The 2014 Guidelines On The Method Of Calculation Of The Attained Energy Efficiency Design Index (EEDI) For New Ships; https://edocs.imo.org/Final Documents/English/MEPC 70-18-ADD.1 (E).docx